- Home

- SVI LINES

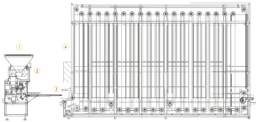

SVI LINES

FOR SEMI-INDUSTRIALS BAKERIES

PRODUCTION RANGE4.500 – 12.000 PCS/H

NUMBER OF ROWS3 - 8

LINE SOLUTIONS

The perfect solution for semi-industrial bakeries. Production performance is customizable, up to 12,000 pcs/h. It’s an ideal complement to mini-line solutions, to accompany our customers in the management of industrial activity.

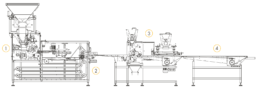

COMPOSITION OF OUR LINES

They are not a simple set of machines, our lines represent true complex systems.

We study, design and assemble each component thanks to

our experience, expertise and precision.

We create line solutions, arranged and programmed to

achieve the same result. Operated as a system,

considered as a unit, organized as a path whose

goal will be the realization of a complete product, yours.

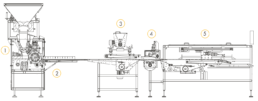

LINE I - 1

CODE

I-1

HOURLY PRODUCTION

Up to 12000 pcs/h* depending on the product/gr

DESCRIPTION

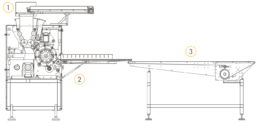

The dough is manually deposited onto the TPC feed belt, which automatically feeds the SVI/SVI+ divider rounder. The rounded dough pieces enter a motorized TP depositing conveyor belt that allows the operator to remove the products.

MACHINERY

- TPC

- SVI/SVI+

- TP

Type of products

Panini

Round Bread

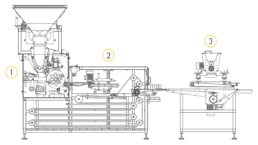

LINE I - 2

CODE

I-2

HOURLY PRODUCTION

Up to 12000 pcs/h* depending on the product/gr

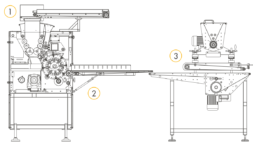

DESCRIPTION

The dough is manually deposited onto the TPC feed belt, which automatically feeds the SVI/SVI+ divider rounder. The rounded dough pieces enter the DTM forming station, which molds them into the desired bread shapes.

MACHINERY

- TPC

- SVI/SVI+

- DTM

Line’s width

Type of products

Hot Dog

Hamburger

Round Bread

Panini

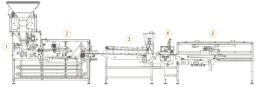

LINE I - 3

CODE

I-3

HOURLY PRODUCTION

Up to 12000 pcs/h* depending on the product/gr

DESCRIPTION

The dough is loaded into the TR-SP hopper, which automatically feeds the SVI/SVI+ automatic divider rounder.

Subsequently, the rounded shapes coming out of the divider rounder enter the DTM forming station, which shapes them into the desired bread shapes. Finally, the products are aligned thanks to the ALL alignment system and positioned automatically on the trays through the model TPS pull-off belt.

MACHINERY

- TR-SP

- SVI/SVI+

- DTM

- ALL

- TPS

Positioning in trays

Line’s width

Type of products

Hot Dog

Hamburger

Round Bread

Panini

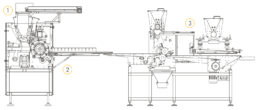

LINE I - 4

CODE

I-4

HOURLY PRODUCTION

Up to 12000 pcs/h* depending on the product/gr

DESCRIPTION

The dough is loaded into the TR-SP hopper, which automatically feeds the automatic divider rounder SVIC with integrated proofing chamber. Next, the rounded loaves that come out of the divider rounder enter into the DTM forming station, which shapes them into the desired bread shapes

MACHINERY

- TR-SP

- SVIC

- DTM

Hydration

Line’s width

Type of products

Hot Dog

Hamburger

Round Bread

Panini

LINE I - 5

CODE

I-5

HOURLY PRODUCTION

Up to 12000 pcs/h* depending on the product/gr

DESCRIPTION

The dough is loaded into the TR-SP hopper, which automatically feeds the automatic divider rounder SVIC with integrated proofing chamber. Next, the rounded loaves that come out of the divider rounder enter into the DTM forming station, which shapes them into the desired bread shapes. Finally, the products are aligned using the ALL alignment system and automatically positioned on the trays through the TPS pull-off belt.

MACHINERY

- TR-SP

- SVIC

- DTM

- ALL

- TPS

Hydration / Positioning in trays

Line’s width

Type of products

Hot Dog

Hamburger

Round Bread

Panini

LINE I - 6

CODE

I-6

HOURLY PRODUCTION

Up to 12000 pcs/h* depending on the product/gr

DESCRIPTION

The dough is manually deposited onto the TPC feed belt, which automatically feeds the SVI/SVI+ divider rounder. Subsequently, the rounded shapes that come out of the rounded dough pieces enter into the MDS-PRO industrial forming station, which shapes them into the formats desired bread shapes.

MACHINERY

- TPC

- SVI/SVI+

- MDS-PRO

Line’s width

Type of products

Hot Dog

Hamburger

Round Bread

Finger Roll

Demi Baguette

Samuli

Arabo

LINE I - 7

CODE

I-7

HOURLY PRODUCTION

Up to 12000 pcs/h* depending on the product/gr

DESCRIPTION

The dough is loaded into the TR-SP hopper, which automatically feeds the SVI/SVI+ divider rounder. Then the rounded loaves that come out of the divider rounder enter the forming station MDS-PRO industrial moulder that shapes them into the desired bread shapes. Finally, the products are aligned thanks to the ALL alignment system and automatically positioned on the trays through the TPS pull-off belt.

MACHINERY

- TR-SP

- SVI/SVI+

- MDS-PRO

- ALL

- TPS

Positioning in trays

Line’s width

Type of products

Hot Dog

Hamburger

Round Bread

Finger Roll

Demi Baguette

Samuli

Arabo

LINE I - 8

CODE

I-8

HOURLY PRODUCTION

Up to 12000 pcs/h* depending on the product/gr

DESCRIPTION

The dough is loaded into the TR-SP feed hopper, which feeds the automatic divider rounder SVIC with integrated proofing chamber. Next, the rounded loaves that come out of the divider rounder enter the MDS-PRO industrial forming station, which then shapes them into the desired bread shapes. Finally, the products arrive on the TP motorized conveyor belt that allows the operator to handle them.

MACHINERY

- TR-SP

- SVIC

- MDS-PRO

- TP

Hydration

Line’s width

Type of products

Hot Dog

Hamburger

Round Bread

Finger Roll

Demi Baguette

Samuli

Arabo

Filone

LINE I - 9

CODE

I-9

HOURLY PRODUCTION

Up to 12000 pcs/h* depending on the product/gr

DESCRIPTION

The dough is loaded into the TR-SP hopper, which feeds the automatic divider rounder SVIC with integrated proofing chamber. SVIC. Next, the rounded dough pieces exiting the divider rounder enter the MDS-PRO industrial forming station, which shapes them into the desired bread shapes. Finally, the products are aligned thanks the ALL alignment system and automatically positioned on the trays with the TPS pull-off belt.

MACHINERY

- TR-SP

- SVIC

- MDS-PRO

- ALL

- TPS

Hydration / Positioning in trays

Line’s width

Type of products

Hot Dog

Hamburger

Round Bread

Finger Roll

Demi Baguette

Samuli

Panini

Arabo

LINE I - 10

CODE

I-10

HOURLY PRODUCTION

Up to 12000 pcs/h* depending on the product/gr

DESCRIPTION

The dough is loaded into the TR-SP hopper, which automatically feeds the SVI/SVI+ divider rounder. The rounded dough pieces enter the CLA proofing chamber for adequate resting time. The industrial forming station MDS-PRO shapes them into the desired bread shapes. The shaped pieces are aligned by the ALL alignment system, passing through the DDS seed distribution system that sprays the product and then deposits the desired topping. Finally, the products are again aligned and positioned automatically on the trays with the TPS pull-off belt.

MACHINERY

- TR-SP

- SVI/SVI+

- CLA

- MDS-PRO

- TP-MOD+RL-ALL

- DDS

- TP-MOD+RL-ALL

- TPS

Hydration / Positioning in trays

Line’s width

Type of products

Hot Dog

Hamburger

Round Bread

Finger Roll

Demi Baguette

Samuli

Panini

Arabo

Filone

LINE I - 11 / L

CODE

I-11/L

HOURLY PRODUCTION

Up to 12000 pcs/h* depending on the product/gr

DESCRIPTION

The dough is loaded into the TR-SP hopper, which automatically feeds the SVI/SVI+ divider rounder. The rounded dough pieces enter the CLA proofing chamber for an appropriate resting time. The LAM laminating station laminates the pieces in the first direction. The shaped pieces are aligned using the TP-RIF alignment system and enter the TPS pull-off belt, which places them on another belt at 90°. The latter belt leads the products to LAM the second laminating station to obtain the form of pizza, puce, piadine and all of the products obtainable by laminating with a diameter of less than 23 cm.

MACHINERY

- TR-SP

- SVI/SVI+

- CLA

- LAM

- TP-RIF

- TPS

- LAM

Hydration / Positioning in trays

Line’s width

Type of products

Pizza

Puccia

Tortilla

Piadina

Pita

Focaccia

Arabo

LINE I - 12 / L

CODE

I-12/L

HOURLY PRODUCTION

Up to 12000 pcs/h* depending on the product/gr

DESCRIPTION

The dough is loaded into the TR-SP hopper, which automatically feeds the SVI/SVI+ divider rounder. The rounded dough pieces enter the CLA proofing chamber for an appropriate resting time. The dual station

LAM (x2) laminating station laminates the parts in the first direction. The shaped dough pieces are aligned by the TP-RIF alignment system and enter the TPS pull-off belt, which places them on an additional 90° belt. The latter belt carries the products to the second double-rolling LAM (x2) to obtain the forming of pizzas, pucce, piadine and those products obtainable from the lamination with a diameter greater than 23 cm.

MACHINERY

- TR-SP

- SVI/SVI+

- CLA

- LAM (x2)

- TP-RIF

- TPS

- LAM (x2)

Hydration / Positioning in trays

Line’s width

Type of products

Pizza

Puccia

Tortilla

Piadina

Pita

Focaccia

Arabo

LINE I - 13

CODE

I-13

HOURLY PRODUCTION

Up to 12000 pcs/h* depending on the product/gr

DESCRIPTION

The dough is loaded into the TR-SP hopper, which automatically feeds the SVI/SVI+ divider rounder. The TP-MULTI multiplying belt doubles the number of rows (from 4 to 8 or 5 to 10). Finally, the rounded dough pieces enter the CLA proofing chamber for an appropriate resting time of about 1 hour. The chamber exit belt is suitable for feeding automatic fryers.

MACHINERY

- TR-SP

- SVI/SVI+

- TP-MULTI

- CLA

Hydration

Line’s width

Type of products

Krapfen/

Berliner

Download our new catalogue

Discover our new product catalogue: our entire range of tailor-made dough machinery.