- Home

- Divide and Round

THE DOUGH INSIDE THE MACHINE IS SHAPED ACCORDING YOUR NEEDS

Kneading by hand is an art.

We want to preserve the traditional gestures with technologies that shape the dough with a customized manufacturing process.

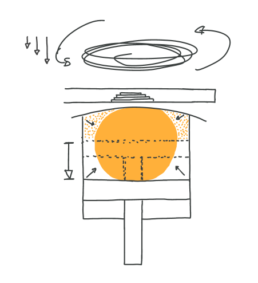

DOUGH FLOW

It takes shape in our volumetric rounding dividers – SV, the beginning of a journey: machinery designed specifically to enhance the art of dough to transform it from raw flow to tangible matter. A manufacturing process consisting of precise steps whose result is always to achieve a precise, tailored, quality end product.

- The dough is placed manually or through an automatic feeding system unside the hopper

- The stars are optimized for the requested products dimensions. they perform the pre-cut, releasing the dough into the deposition chamber

- The piston presses the dough into the drum, which retracts the set hexagons size, creating the dough's required volume

- The drum rotates 90 degrees and cuts the pieces through the scraper

- The dough inside the hexagons arrives at the rounding station, where the rounding plate, combined with the internal movement of the hexagons, rounds the dough

- The drum’s subsequent rotation brings the rounding pieces to the front station, where the hexagons execute the ejection on the output belt, carrying the rounded pieces outside

OUR TECHNOLOGY

DRUM RANGE

It is in the drum that the dough takes shape. High customization allows you to choose from different weight ranges and up to 4 different shape combinations. SA, DA or SUPERFLEX: more solutions for every need.

DIVIDING SISTEM

The breaking system, working volumetrically, ensures consistency and repeatability of the process. The cutting knife and the correct flour metering system allow high levels of precision to be achieved. The calibrated first cut and adjustable pressure make it possible to preserve the quality of dough, even the softest and most delicate ones.

ROUNDING PROCESS

The rounding process is highly adjustable: the system that creates the movement can be set in terms of both speed and quantity. All components work synergistically and in coordination to ensure not only the highest quality of rounding, but also a ‘wide adaptability, respecting the characteristics of different doughs.

SVI+

7.500 – 15.000 pcs/h

5 – 10 rows

Automatic volumetric divider perfect for semi-industrial and industrial bakeries. The production performance can be customized to reach a maximum of 15.000 pcs/h. The lines are customized according to the customer’s needs both in terms of performance, design and automation.

Download our new catalogue

Discover our new product catalogue: our entire range of tailor-made dough machinery.

Nothing found.